Toyota Argentina has been operating in the country for 26 years. It represents 40% of the exports of automotive companies in 2019 and currently has an annual production capacity of 141,000 units, exporting 75% of its production to 22 Latin American countries and to the Caribbean.

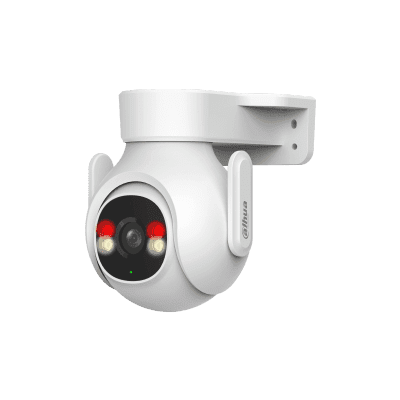

Toyota’s Zárate plant in Argentina, which was closed due to COVID-19, is ready to reopen with new regulations to ensure the security of its employees. Given the need to apply a health protocol against the pandemic and resume a safe operation, Toyota Argentina carried out an analysis of the new technologies on the market and chose the Dahua Thermal Body Temperature Monitoring Solution for its high quality and high cost-performance value.

Safety at the factory

Due to the large number of people entering and leaving the factory every day, the automaker required a safe and efficient solution to help them control the commuting staff (including 1,500 employees that take buses, 900 employees that use parking lots and 700 contractors) without delays, while complying with the new government regulations.

The solution included 4 sets of Dahua Thermal Body Temperature Monitoring equipment (DHI-NVR4216-I + TPC-BF-5421 + Blackbody). They were installed in different entrances, providing a non-invasive way to check the body temperature of their employees at the same time, ensuring that the temperature of the people entering the plant is normal.

Maximising employee security

“This situation took us from having two production shifts before the pandemic to one production shift only, having to rise the number of buses to bring employees and contractors to the plant, as well as applying additional security measures in dining rooms, common areas, and production line for social distancing and cleaning and hygiene measures,” said Alberto Martín López, Corporate Security Manager at Toyota Motor Corporation.

The training of personnel was also conducted to allow them to be familiar with the equipment"

“Before this implementation, every shift entered and leave the plant in 30 minutes. Now, maintaining a rhythm of fluid access and social distancing, we do it in 45 minutes but in a more secure way, ensuring a competitive timing and maximising our employees’ security,” explains López regarding the immediate benefit of the solution in the daily operation of the company.

Production resuming

“The installation and calibration was relatively quick. The Zárate Plant was operational in 3 days, with the addition of some infrastructure improvements on the entry/exit areas, since work was carried out in semi-open places and the impact of climate changes had to be reduced. In this period, the training of personnel was also conducted to allow them to be familiar with the equipment and to ensure the equipment’s usage life,” he added.

In addition, López also mentioned that “The current COVID 19 protocol was also implemented, randomly testing staff that reaches about 100 tests daily. These types of new technologies facilitate and maintain a safe production operation and care for our employees and contractors, allowing us to comply with the demand of our customers.”

Business security

This reinforces Dahuas commitment to provide solutions that aid prevention measures during this pandemic"

The Dahua Thermal Body Temperature Monitoring equipment is faster than hand-held scanners and can screen massive number of employees at a safe distance, enabling efficient entry/exit access for employees. It provides security guarantee for Toyota Argentina’s reopening and routine operations, while meeting the government’s business resumption requirements.

"This technology allows companies to return to business in an orderly manner and be compliant with the measures dictated by official entities. This reinforces Dahua Technology's commitment to provide solutions that aid prevention measures during this pandemic. The objective is to be able to continue offering solutions that facilitate community care by supporting the economic business resumption of industries,” says Franky Su, Dahua Technology Country Manager for Argentina & Uruguay.

Specific solutions and products might vary depending on the different regulations and measures for COVID-19 in each country.

From facial recognition to LiDAR, explore the innovations redefining gaming surveillance